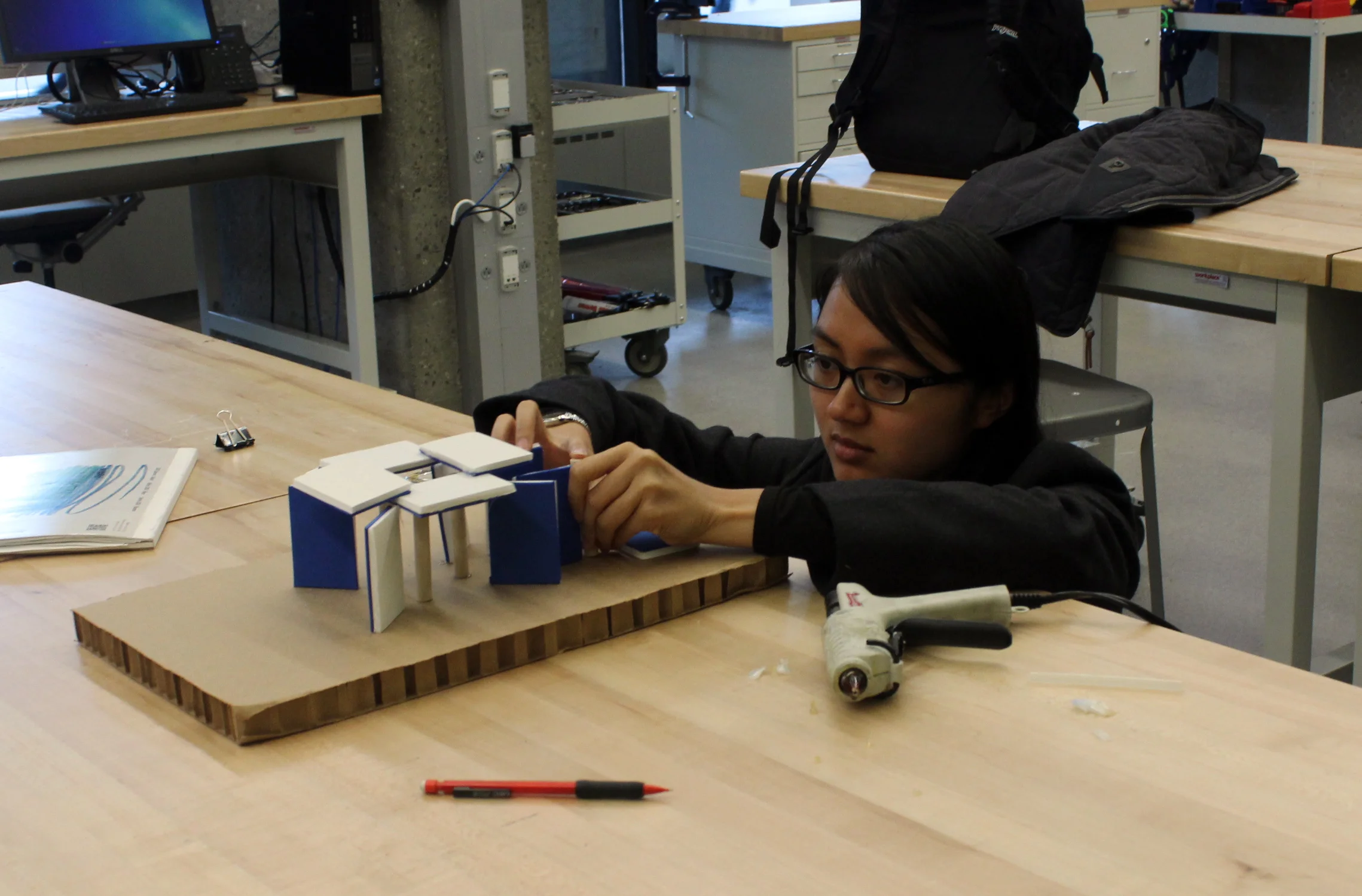

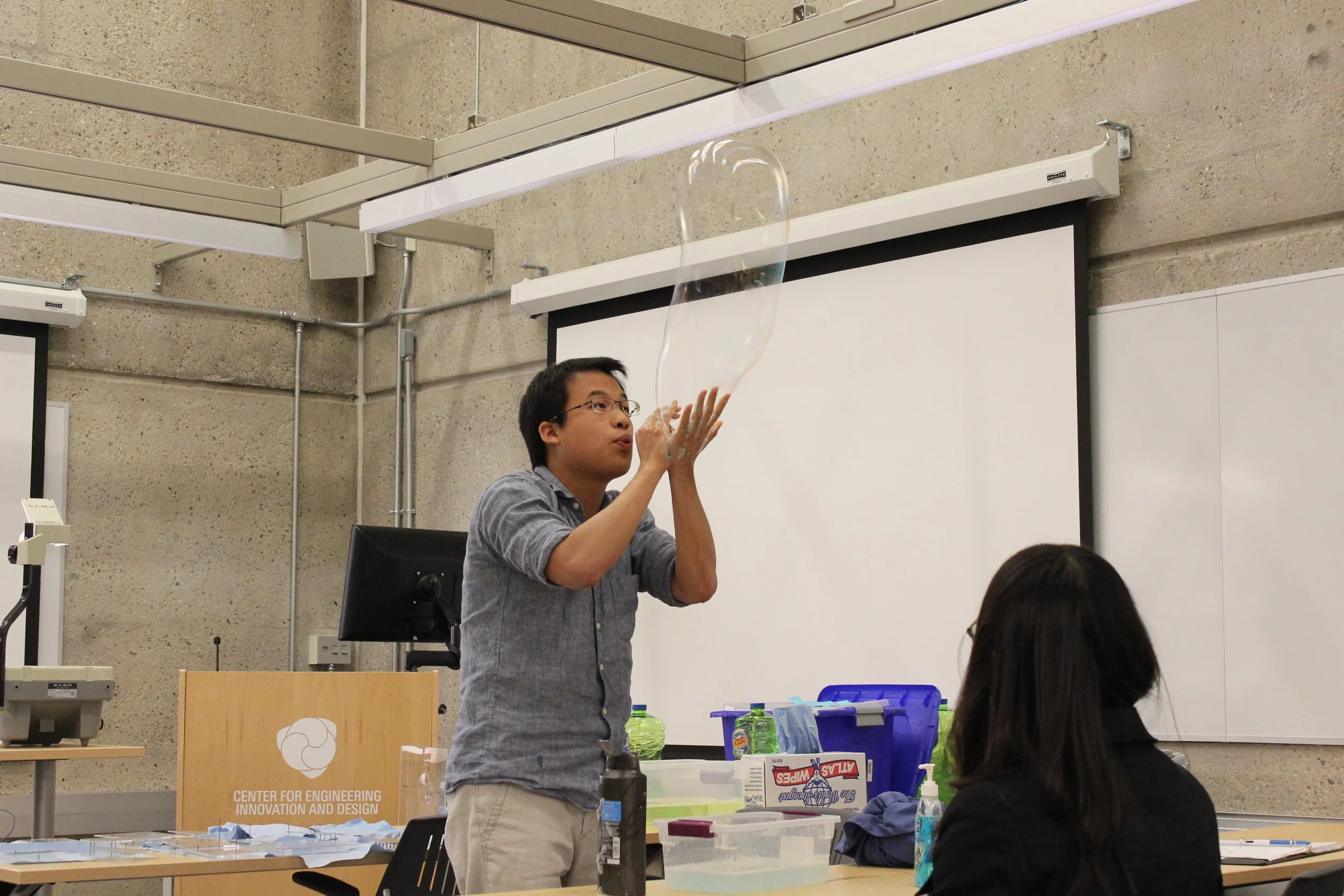

The students enrolled Mechanical Design: Process and Implementation (MENG 489) have taken on the challenge of designing, prototyping, and producing a number of engineering projects. The class, taught primarily by Dean Wilczynski in the CEID, focuses on the study of the design process from beginning to end. The projects began as a list of suggestions, added to by the students themselves. The projects chosen range from UAVs to an Ice Core Analysis machine to a scale meant for use in space. At this point, having chosen a project and rough design, the teams are prototyping and modeling. Some of the students in each group took the time to share the details of their projects and their experiences thus far.

The UAV project was suggested by students in the class with the goal of participating in the ASME Lighter than Air UAV Competition in April. The competition requires a radio controlled and battery powered UAV that can navigate through a series of gates, drop a payload on a target, and return to its original position. The suggestion was so popular that two teams formed.

Team Blue: UAV One

The UAV One project is one of the two groups having the initial goal of competing in the ASME competition. Their design process began with a look at constraints, such as anded for a battery, and objectives that define the performance of the UAV. The design, a multicopter, was chosen because it best fit the objectives and constraints the team discussed. A multicopter has a high maneuverability and can carry a large amount of weight compared to their original choice, a blimp, which would have been able to blue for longer.

The group is now prototyping the components of the UAV and building them separately. Some parts have been ordered, but that competition requires the UAV be of the team’s design. Many of the parts will be produced from raw materials in the CEID. Jan Kolmas (’14), a member of the team, thought that they would be “likely to use every single aspect of the CEID in this project.”

Team Orange - UAV Alpha

UAV Alpha is also working on a project for the ASME competition. Jason Allmaras (’14), a member of the team, said that the competition restriction to a 28” diameter poses a “unique set of design considerations.” In order to stay on schedule and best utilize the specific skills of each member the team split the design up into subsystems to be designed by subgroups.

Currently the team is considering the benefits of a modified helicopter style craft or quadcopter. In the next week the group hopes to collect data to determine the best solution using a test stand of their own design. Prototyping, much of which will occur in the CEID, should be finished by the end of October.

The team expects to use the electronics workstation quite frequently in the implementation of the design. The lightweight plastic from the 3D printers is another resource which will be useful in creating a successful craft.

The long-term goal is for the Yale Undergraduate Aerospace association (YUAA) to fly the UAV at the competition in the fall of 2014.

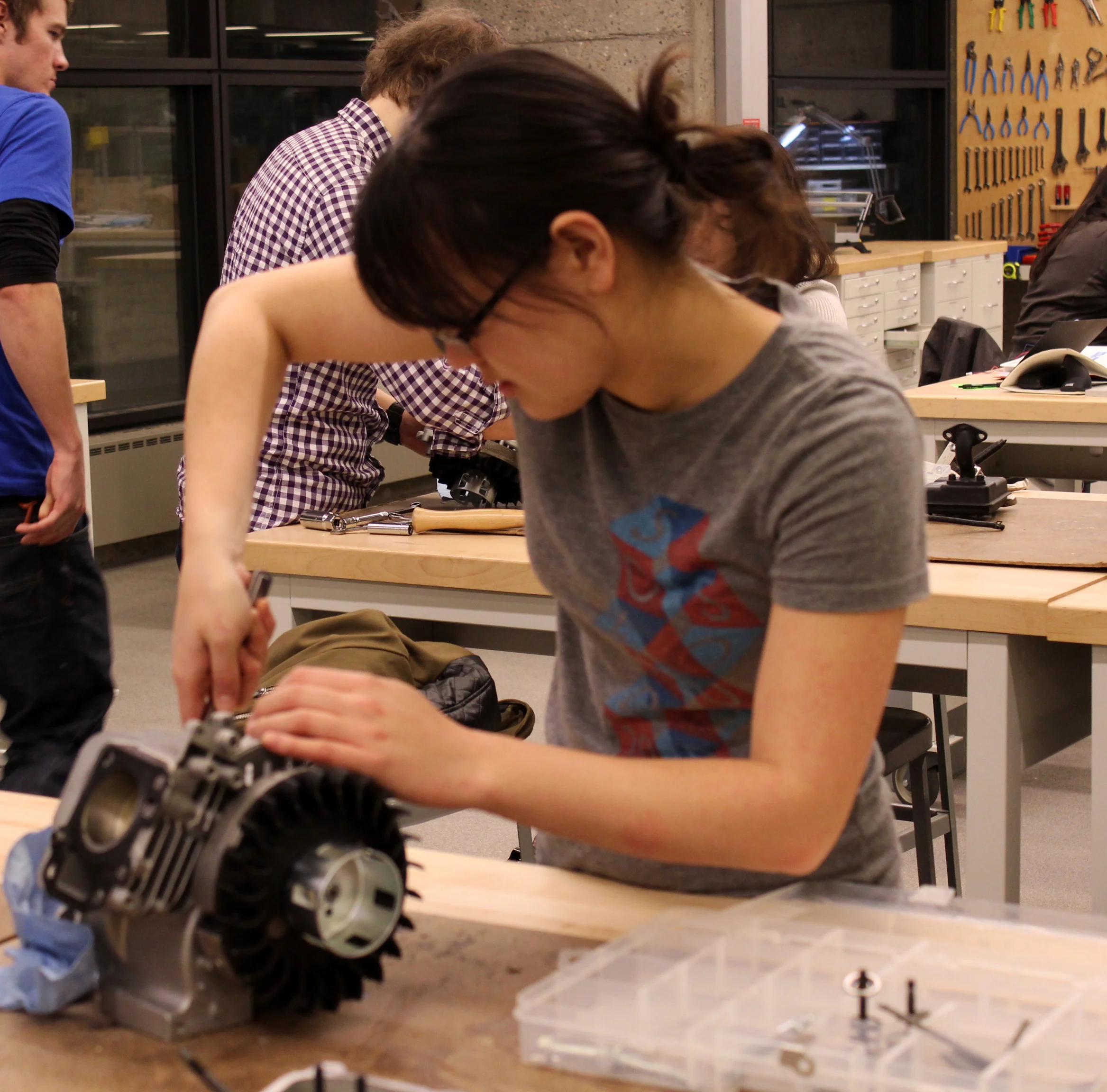

Team Red - Ice-Core Analysis

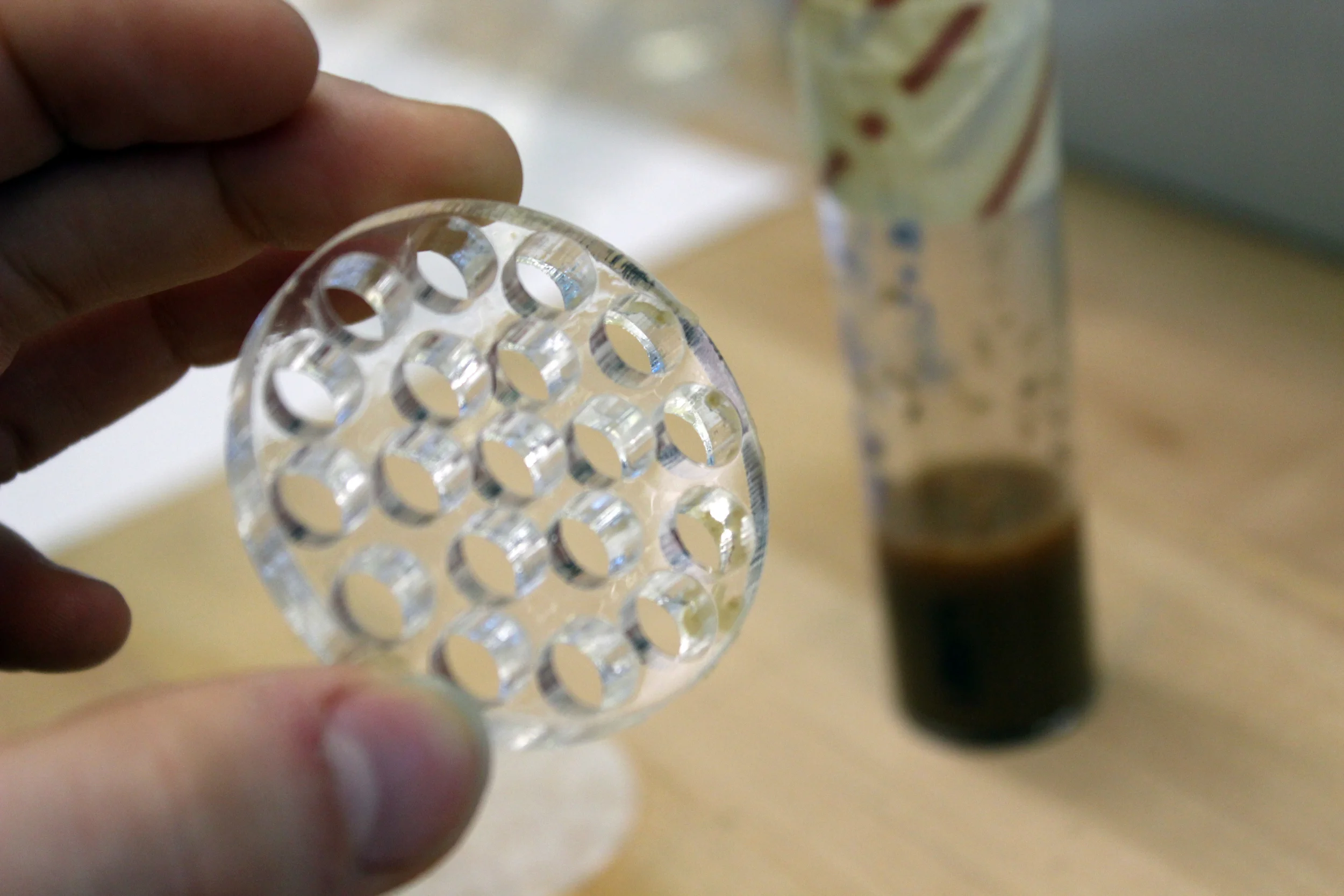

A third team is designing an Ice Core Analysis machine which will determine the grain orientation of the crystals and shine light on past climate changes. The grain orientation of the ice can be used to help understand the flow history of the ice. The device will use polarizers and cameras to analyze a chunk of ice.

Current methods for this type of analysis are on the expensive size and not terribly portable. The group hopes to address these two issues and make the images better resolution and in color. The new design will involve two cameras in order to reduce the stages of movement of the analysis. The device must function from at temperature ranging from -25 to -40 degrees Celsius so the team not only has to make sure the device works at this temperature, but also has to consider the feasibility of being able to use small controls wearing bulky gloves and clothing. They hope to have the process be completely automated.

The team also researched ice core research itself and how the images would be used to optimize the design. The project is based off of improving a machine in Dr. Wilen’s lab, so the team has also been able to look into compatibility and understand first hand the design challenge.

Levi DeLuke (’16) has found the device was not easy to visualize which made the design process more difficult. They have used K’NEX to help with the visualization and are now moving into SolidWorks. The team anticipates using the CEID to machine the aluminum frame and most of the mechanical parts of the device. If they can find parts that work within their temperature constraints the team would like to purchase parts to keep the cheap and reproducible goal of the project in mind.

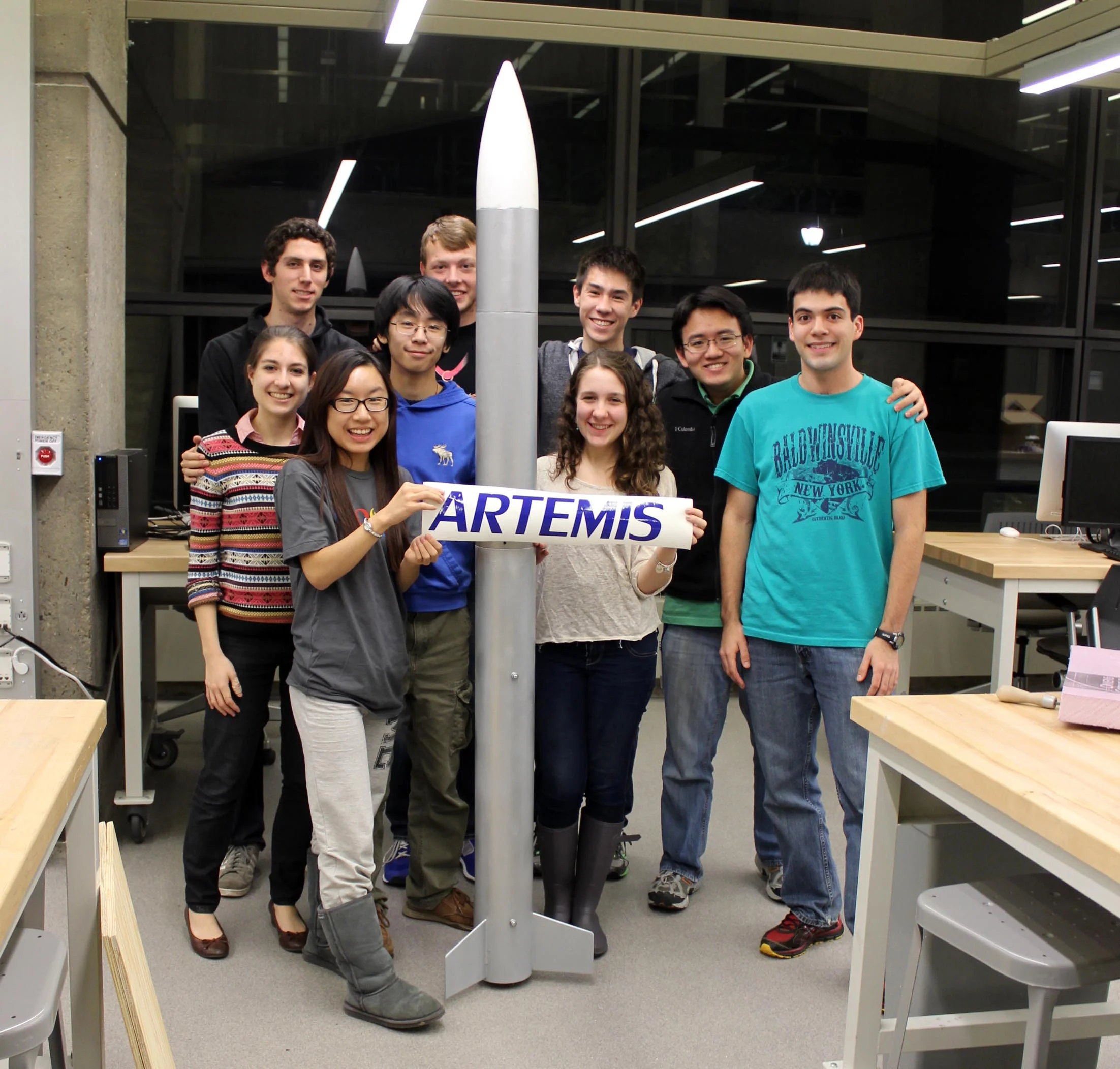

Team Green – Space Scale

The final group is designing a microgravity object scale with will be able to determine the mass of an object in space. The design is focusing of objects with masses between one and five kilograms, as NASA does not currently have a way of massing objects in this range. They have a way of massing astronauts and are developing a system for taking the mass of very small objects less than one kilogram, but lack a system for masses in between.

Typically scales use gravity to function. The team’s design mimics the effects of gravity by creating an acceleration which allows for the measurement of the object’s mass from the resultant force. Their design uses an oscillating system and employ a load cell to measure the force. They will be ordering a stepper motor to drive these oscillations, and many of the other parts of the body of the device will be composed of lightweight metals or composite materials. Charlotte Guertler (’14) noted that the team hopes to achieve an accuracy of 10% and a precision of 0.2 kg as quickly as possible while keeping the weight and volume of the system to a minimum.

Matthew O’Donoghue (’14) has found the design process to be exciting so far. Matthew has learned “everything from developing a weighted decision matrix to how astronauts get weighed in space to how to use Microsoft Project.” In the design process the team encountered the challenge of going from an abstract idea to a concrete plan with specific parts which fit together.

They hold all of their meetings in the CEID and have used the available materials so far to visualize the devices size and understand constraints. “The CEID has been our Mission Control… This transition from the abstract to the concrete is exactly the creativity the CEID fosters,” Matthew says.

The team hopes to see their scale on future space missions.